Versiglyde Composites consist of a range of advanced composites materials; fibre reinforced resin bonded composites, ideally suited to highly loaded bearing applications in a variety of environments.

Versiglyde Composites consist of a range of advanced composites materials; fibre reinforced resin bonded composites, ideally suited to highly loaded bearing applications in a variety of environments.

The range of marine materials were developed to give improved performance, longer life and the capability of operating under non-lubricated conditions; offering a maintenance free “Fit and Forget Bearing Solution” in a variety of marine environments.

Grades – laminated composites composed of synthetic fabrics impregnated with thermosetting resins and solid lubricant fillers – offer engineers a real and effective alternative to traditional bearing materials.

Versiglyde Composites

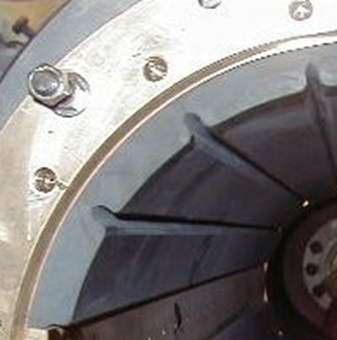

Stern Shaft Stave Bearings

VERSIGLYDE stave bearings offer a superior performance envelope coupled with a competitive price and short delivery time when compared to other currently available stave bearing materials. Consequently our stave bearings are now being specified for use on commercial vessels and navies worldwide.

VERSIGLYDE stave bearings are manufactured from highly engineered composite materials especially formulated to provide both slow and high speed, high load operation offering longer bearing and shaft life.

The unique formulation of our stave bearing materials coupled with their low friction provides an inherent vibration damping characteristic resulting in a low/nil noise signature. Each grade of material is also non polluting and hence environmentally friendly.

VERSIGLYDE Stave Bearings are precision machined ready to be fitted together in the housing to form a complete bearing which is then finish machined in the bore to give the optimum running clearance. They can be designed, manufactured and supplied for new build or spares replacing rubber, lignum vitae, cotton, UHMW polyethylene and other plastic type materials.

For stave design, fitting information and running clearance or any other information please contact our marine design team.

Advantages in using VERSIGLYDE materials

- Competitive price Short delivery time

- High strength characteristics

- Low friction and wear characteristics

- Can operate under dry running Excellent dimensional stability

- Low ‘stick slip’ Low/nil noise signature

- Runs hydro dynamically at low rpm Low swell

- Low shaft wear

- Low creep resistance

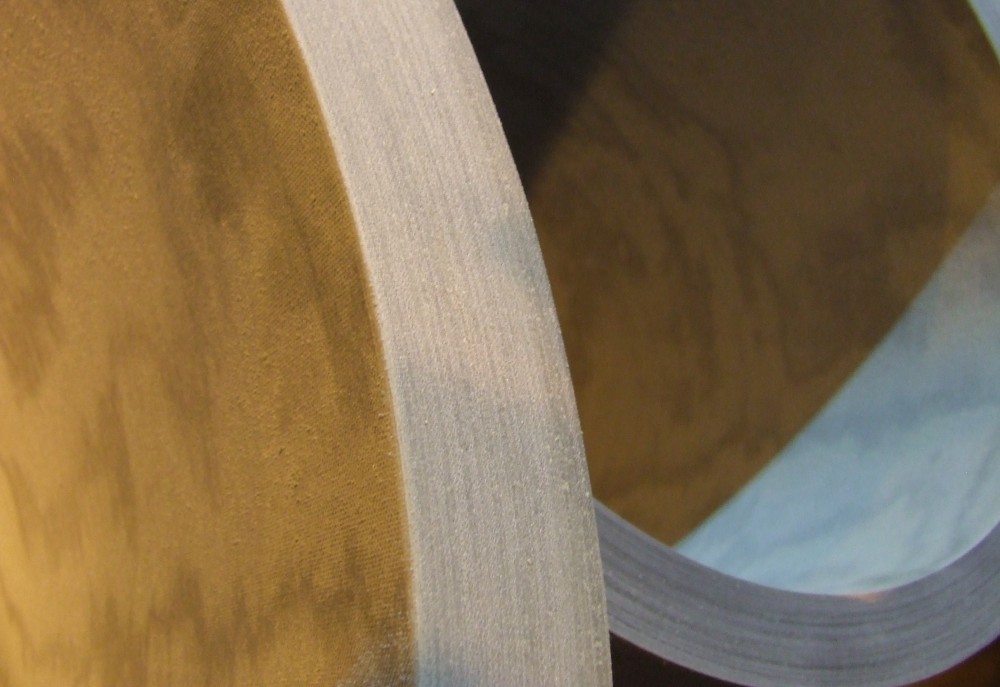

Rudder Bearings

The result of an extensive rudder bearing R&D program and was initially launched into the marine market in 2001. It has since been installed and successfully operated on over 2,000 vessels, both new and repair, on various shaft sizes up to 1.25 metres diameter.

The material was developed to give improved performance, longer life, a very competitive price and to have the capability of operating under non- lubricated conditions, offering a maintenance free…

‘Fit and Forget Bearing Solution’

Due to its excellent bearing characteristics Versiglyde Composites have classification approval for both lubricated and dry operation, making it the ideal rudder bearing material.

Other applications include; deck machinery equipment, offshore mooring systems, steering gear, stern roller bearings, water tight door bearings and many more.

Advantages in using Versiglyde Composites for rudder applications

- High load capability

- Approved for wet and dry operation

- Very low stick - slip

- Short delivery time

- Good elasticity

- Dry, oil, grease, water operation

- Can be freeze fitted

- Classification approval (10 N/mm2)

- Very low swell

- Low wear characteristics - long life

- Maintenance free

- Good dimensional stability

- Competitive price

- Environmentally friendly

Water Lubricated Propeller Shaft Bearings

Available from VERSIGLYDE Bearings has been specifically developed for the requirements of brown water lubricated propeller stern shaft bearing applications in river boats and work boats; offering a maintenance free…

‘Fit and Forget Bearing Solution’

Versiglyde has been tested for stern tube bearing applications and has been proven to offer superior performance in terms of wear, extended life and low shaft wear over other water lubricated propeller shaft bearing materials.

The material is available as finish machined bearings or in billet form for final machining in the ship yard.

The excellent bearing performance coupled with its superior physical characteristics offers shipyards and ship owners operating in harsh conditions many advantages.

Advantages in using Versiglyde Composites in your propeller shafts

- High load capability

- Approved for wet and dry operation

- Very low stick- slip

- Short delivery time

- Good elasticity

- Dry, oil, grease, water operation

- Can be freeze fitted

- Classification approval (10 N/mm2)

- Very low swell

- Low wear characteristics - long life

- Maintenance free

- Good dimensional stability

- Competitive price

- Environmentally friendly

MARINE BEARINGS

Due to their excellent mechanical, physical and bearing characteristics VERSIGLYDE materials are ideally suited for the Marine Industry where reliability, long life, limited maintenance and zero down time are of paramount importance.

In addition to their intrinsic bearing properties the VERSIGLYDE range of materials also have the distinct advantage of resisting marine growth, cathodic chalking and bi-metallic corrosion making them the ideal bearing solution.

The VERSIGLYDE range of materials can operate under dry, grease, sea water or oil lubrication and can be used against many different mating surfaces including hardened steel, stainless steel; chrome plated steel, nitrided surfaces and many other corrosion resistant surfaces. In addition it has been shown that the wear of the VERSIGLYDE range of materials is considerably less than other plastic type materials and with minimal surface damage to the counter face a longer life can be achieved.

As a world class supplier VERSIGLYDE Bearings offers a professional service with technical support from their experienced team of plastic technologists/application engineers including, design recommendation, technical proposals and quotation, machining recommendations and bearing installation assistance.

Benefits

- Competitive price

- High load capability

- Excellent shock resistance

- Good elasticity

- Good dimensional stability

- Pollution free operation

- Low creep

- Short delivery time (repair 48 hours)

- Counter face friendly

- Excellent corrosion resistance

- Low swell characteristics

- Low friction

- Low wear rate - long life

- Resistant to marine growth

- Deck equipment

- Winches

- Container Pads

- Stern rollers

- Launch systems

- Tow pins

- Pipe rack support bearings

- Drill rigs & ships

- Cranes

- Landing systems

- Inspection lifts

- Shark jaw bearings

- ROV submersibles